Details

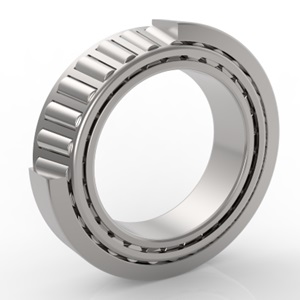

Tapered roller bearings are assemblies consisting of a solid, ribless outer ring, an inner ring with boards of various heights and a roller assemlby. The roller assemlby, together with the inner ring forms an assembly unit. Open bearings are not self-retaining. The outer ring can be removed. Thus, separate assembly is possible which makes fitting easier. There is a great number of different designs: single-, double- and multi-row. Single-row tapered roller bearings absorb high radial and one-sided axial forces.

For opposing axial loads a second single-row tapered roller bearing is usually set opposite in an X- or O-arrangement. The two bearings are then set opposite to each other until the desired bearing clearance or desired pre-load is reached. Bearing units with pre-set bearing clearance or pre-load are double- or four-row tapered roller bearing units. These are special bearings. The previously defined desired axial clearance for the individual case is maintained in assembly if the recommended tolerances of the adjacent construction are adhered to.

Special bearing

- 涂层轴承

- Single-row tapered roller bearings in inch dimensions

- Double-row tapered roller bearing (in metric and inch dimensions, in O- arrangement (TDO) or X-arrangement (TDI))

- Four-row tapered roller bearing (in metric and inch dimensions, in O-arrangement (TQO) or X-arrangement (TQI))

- Customer-individual construction

Manufacture sizes

From an outside diameter of 100 mm.

Designs

- Single-row metric tapered roller bearing

- Aligned bearing sets in O- or X-arrangement

Bearing ring materials

Roller bearing steel (Standard)

Rolling elements materials

Roller bearing steel (Standard)

Heat treatments

Martensitic hardening (standard), case hardening

Cage materials

Brass, pin type cage with perforated rollers, synthetic material

Main dimensions

The main dimensions of the standardised tapered roller bearing comply with DIN ISO 355 and DIN 720.

Dimensional and running accuracy

We manufacture standardised metric tapered roller bearings of tolerance classes normal to P5 as per DIN 620-2. (P5 up only up to 250mm)

Bearing clearance

–

Contact angle

–

Lubrication

The open bearings are not greased and can be lubricated with grease or oil.

Connection with adjacent construction

Positive locking shaft-hub Connection