Details

The performance capability of rotary construction components in use can be improved by appropriate coatings: Corrosion protection, wear protection, reduction of friction forces und electrical insulation. Compared with special materials (e.g. rust resistant roller bearing steels), coatings are often cheaper – especially galvano-technically produced metallic coatings..

Corosion protection

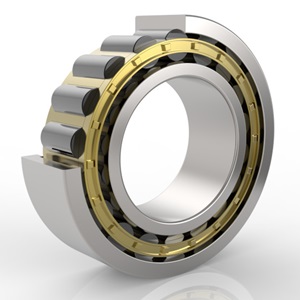

Cylindrical roller bearings with improved protection against corrosion

Aluminium raceway system with anti-rust protectionAluminium raceway system with anti-rust protection

The chrome steel 100Cr6 predominantly used for roller bearings corrodes when in contact with water or air humidity. Where there is moderate corrosion risk, a combination with a corrosion-proof coating is an economical solution.

Depending on the alloy components of the coating and the coating thickness, the coated parts receive corrosion protection as per the salt spray test as per DIN EN ISO 9227 between 24 and 72 hours against red rust Formation.

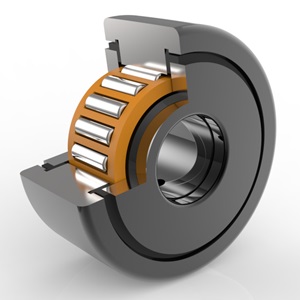

Coated surface of a stud type track roller in order to reduce wear

Coated rollers of a cylindrical roller bearing in order to reduce wear

Limited or poor lubrication conditions can lead to increased abrasion and adhesive wear up to tribo oxidation. This danger can be encountered for or the risk reduced with an appropriate coating.

Adhesive wear occurs mostly in parts in contact which have the same bonding properties, e.g. metal/metal under high pressure. The contact surfaces adhere to each other so that when they slide, edge layer particles are carried away. To avoid this process, it is often enough to change the properties of the upper surface of one of the components.

Abrasive wear occurs when the rough peaks of one contact part pierces or rubs on the surface layer of the other component. Scoring, micro-chipping and abrasion occur. This is why abrasive wear is also known as erosive wear. Tribological coating can prevent abrasive wear by covering one of the contact parts with a protective layer, the hardness of which is above the hardness of the basic material.

Tribo oxidation or reaction layer wear arises where there is a tribological demand due to chemical reactions. Reaction products are formed on the edge layers of the contact parts, which are deposited as intermediate layers e.g. oxide layers and are mechanically destroyed by the relative movement of the sliding parts. An example of this is frictional corrosion. Along with constructive changes, this can be helped by suitable coating solutions, which prevent the chemical reactions because of their bonding properties.

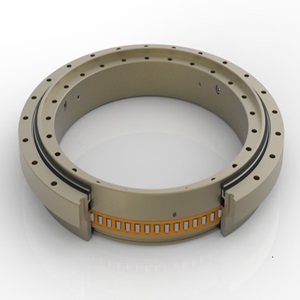

Where there is an electric current, there is a danger of damage to the raceways or the rolling elements and premature aging of the lubricant. The result is the premature and uncontrolled failure of the bearing. To counter this risk, so-called isolated bearings are used in engines, generators etc. Electrical current flow between housing and shaft is prevented using non-conducting ceramic components (e.g. silicon nitride rolling elements) or ceramic coatings of the outer ring outside surface or the inner ring bore.

The insulation layer is determined by the electrical and mechanical stress.