The mobility of tomorrow requires careful use of resources, improved safety and the possibilities of it. This applies to two-wheeled vehicles, cars, special and commercial vehicles, rail transport and air and space travel.

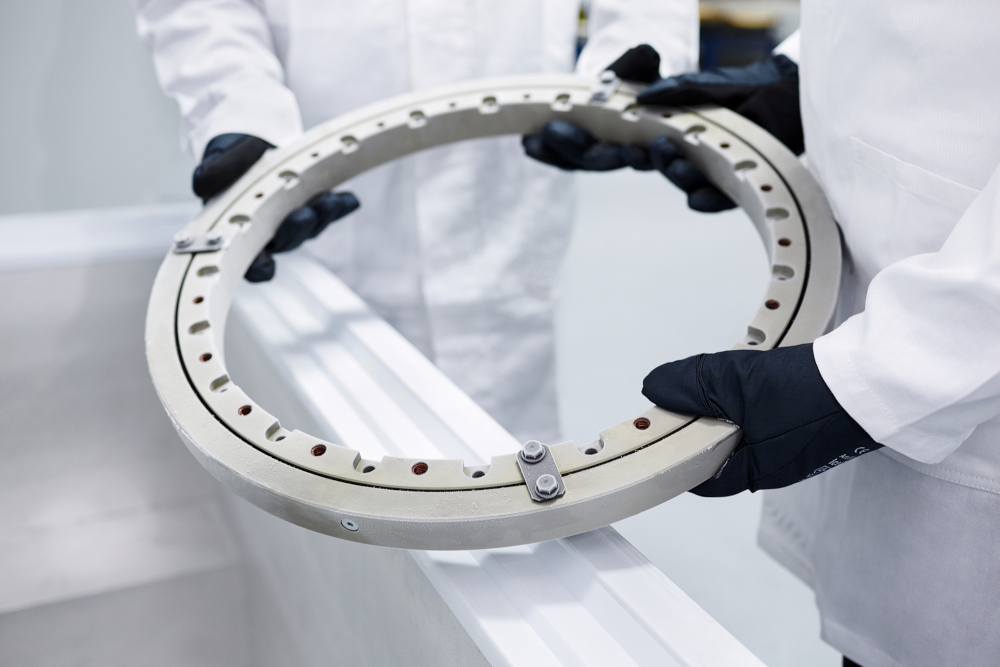

Raceway system | aluminium bearing for special vehicles

Light raceway systems create an open-centre connection between vehicle chassis and the vehicle shell. For this the bearing had to fulfil the following requirements:

- Temperature range from -46°C to +73°C

- Corrosion resistance even against air containing salt

- Taking radial, axial loads, tipping moments and impact loads

- Fulfilment of maximum weight specifications

- Enabling relative movement between vehicle chassis and vehicle shell

- Life-long lubrication

- Low, even friction moment over the entire temperature range and non-planar joint surfaces

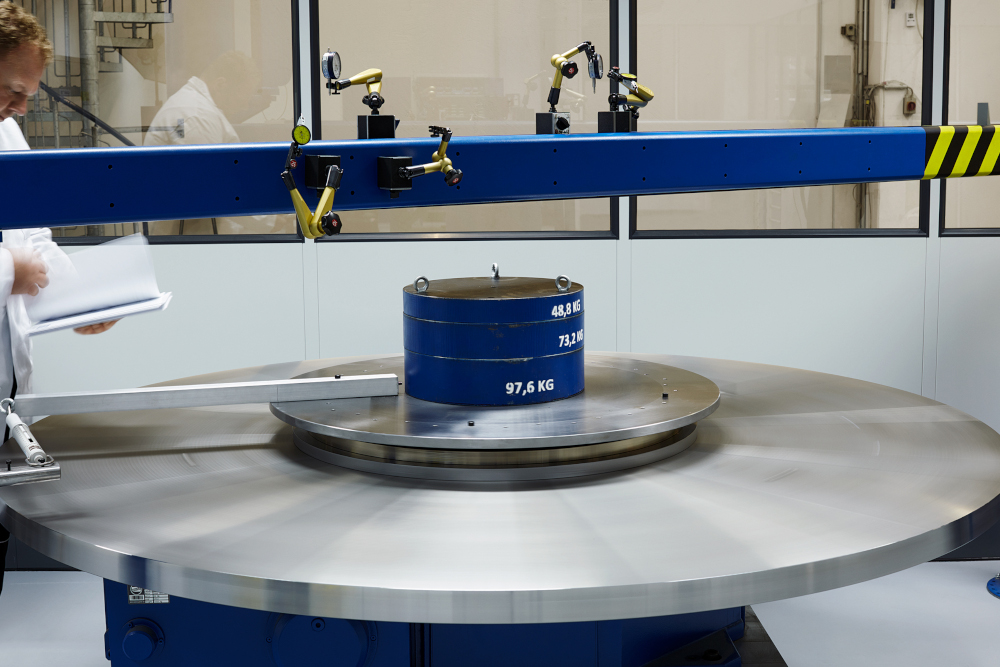

Cooling of raceway systems to simulate application conditions

Friction torque measurement under simulated application conditions

These requirements can be met with the use of surface-treated highly solid aluminium wrought alloy for the bearing ring. The raceway system as well as the rolling elements consist of corrosion-resistant steel. By separating the bearing ring from the roller contact, the raceway system can move relative to the bearing ring. Thus, the system is not sensitive to the effects of temperature and non-planar joint geometry.

The standing bearing ring is toothed. Thus, the side-direction drive of the vehicle shell can be moved relative to the vehicle Chassis.

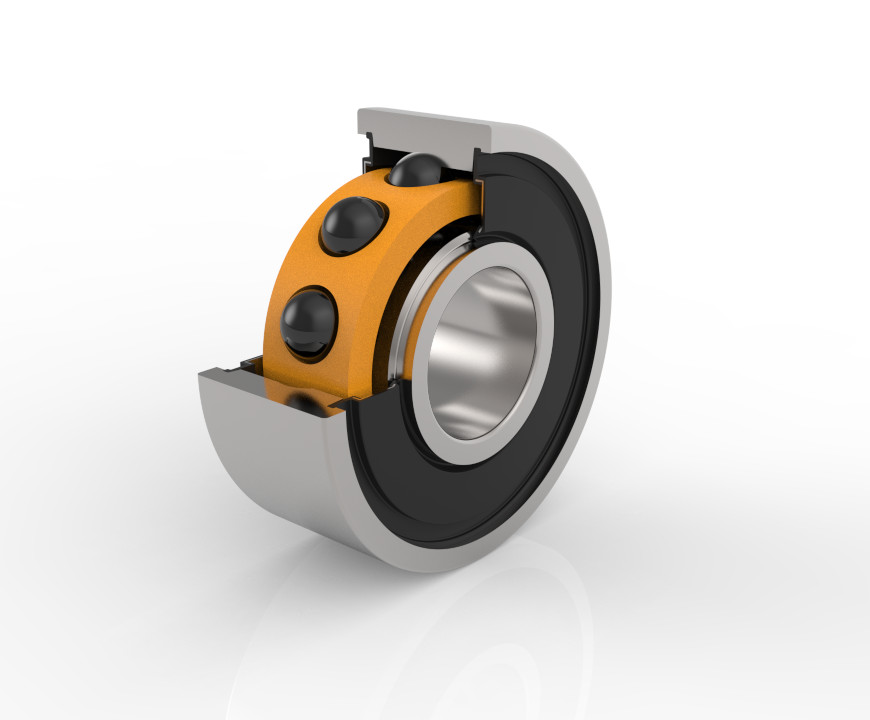

Hybrid bearing for heavy goods vehicle drive train

Development of the drive train in the automobile industry must significantly reduce the limiting values for the emission of harmful substances to comply with legal requirements.

For this reason, amongst other things, greater use of exhaust gas return is being investigated. Bearing solutions are being developed for this which fulfil the following requirements:

- Very high operating rotational speeds

- Use of the bearing in media which require the use of corrosion-resistant steels and do not exhibit low load factors

- Use of sealing materials for these media

- Use of cage materials suited to operating temperatures of 200°C, still exhibiting high shape integrity

- Long lifetime requirement with >150 Tkm run performance

IBO hybrid bearings impress by using special steels for the bearing rings as well as using ceramic balls. The angular ball bearing is manufactured to a precision of P4 according to DIN 620. The contact angle and the bearing layout are designed so that the bearings run without any play over the whole temperature range. IBO hybrid bearings fulfil the high demands in running performance through this design.

Other examples of IBO-bearing solutions for mobile applications

Special swivel Joints to accommodate tilting moments

Slewing rings

Special cylindrical roller bearings with improved corrosion protection

Coated bearings