Details

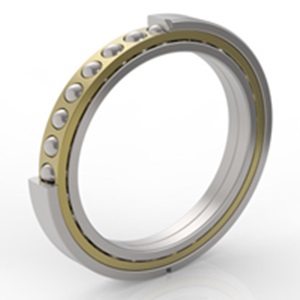

Four point contact ball bearings resemble in their construction a pair of single-row angular contact ball bearings in O-arrangement and thus also double-row angular contact ball bearings. Four point contact ball bearings – they have only one row of balls- thus save significantly on installation space in the axial direction. Because of their geometry, they are especially suited to absorbing high axial forces from changing directions.

Special bearing

- Coated bearing

- Thin-section four point contact ball bearing

- Customer-individual construction

Manufacture sizes

Individual manufacture beginning at outer diameter of 250 mm – serial manufacture even at the smallest diameters.

Designs

- With inner ring split in radial direction (QJ)

- With outer ring split in radial direction (Q)

Bearing ring materials

Roller bearing steel (Standard)

Rolling elements materials

Roller bearing steel (Standard)

Heat treatments

–

Cage materials

Brass, sheet steel

Main dimensions

The main dimensions of the standardised four point contact ball bearing comply with the details in DIN 628-4

Dimensional and running accuracy

We manufacture angular contact ball bearings of tolerance classes normal to tolerance class P4 as per DIN 620-2. We manufacture double-

Bearing clearance

We manufacture four point contact ball bearings with bearing clearances C2, normal, C3 and C4 as per the details in DIN 628-4, up to individually limited clearance classes. The values apply to non-built-in bearings with zero measurement load.

Contact angle

Usually 35°

Lubrication

The bearings are not greased and can be lubricated with grease or oil.

Connection with adjacent construction

Positive locking shaft-hub Connection