Details

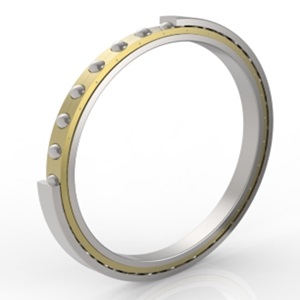

Deep groove ball bearings are self-contained radial ball bearings with many uses. They are suitable for the higher and the highest rotational speeds due to their very low frictional moment. They consist of solid outer rings, inner ring and ball cage assembly.

Special bearing

- Coated bearing

- Thin-section deep groove ball bearing

- High-precision deep groove ball bearing

- Hybrid bearing

- Ceramic bearing

- Customer-individual construction

Manufacture sizes

Individual manufacture beginning at outer diameter of 250mm- serial manufacture even at the smallest diameters.

Designs (single-row)

- Both sides open bearing (standard design)

- Single or both-sides sealed bearing

- Bearing with radial groove in the outer ring

- Matched bearing sets (in O-, X- or tandem-Arrangement)

Bearing ring materials

–

Rolling elements materials

Roller bearing steel (standard), ceramic, corrosion resistant steel

Heat treatments

–

Cage materials

Synthetic material, brass, steel sheet, steel

Main dimensions

The main dimensions of the standardised single-row deep groove bearing correspond to the details in DIN 625-1.

Dimensional and running accuracy

We manufacture single-row deep groove ball bearings of tolerance class normal to tolerance class P4 according to DIN 620-2.

Bearing clearance

We manufacture single-row deep groove ball bearings with radial bearing clearance C2, normal, C3, C4 and C5 (not included in DIN) as per DIN 620-4, up to restricted clearance classes or to individually adjusted bearing clearance classes through optimisation of the osculation.

Contact angle

–

Lubrication

The bearings can be lubricated by grease or oil. For sealed bearings, the type and quantity of lubricant can be adjusted to the individual need in each case to enable a long lifetime.

Connection with adjacent construction

Positive locking shaft-hub Connection