Details

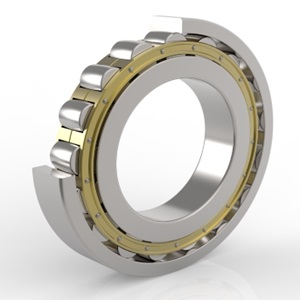

Barrel roller bearings are single-row self-aligning roller bearings. Because of their hollow-ball raceway in the outer ring and the symmetrical spherical roller, the roller assembly can adjust itself when there are misalignments or shaft deflections. Barrel roller bearings are particularly suited for bearings which have to absorb high, impact loadings and where alignment errors must be corrected. They have a low axial load capacity.

Special bearing

- Customer-individual constructions

Manufacture sizes

From an outer diameter of 100 mm.

Designs

- Barrel roller bearings with cylindrical or tapered bore with accompanying clamping sleeves

Bearing ring materials

Roller bearing steel (Standard)

Rolling elements materials

Roller bearing steel (Standard)

Heat treatments

–

Cage materials

Brass, synthetic material

Main dimensions

The main dimensions of the standardised barrel roller bearings comply with the details in DIN 635-1.

Dimensional and running accuracy

We manufacture standardised barrel roller bearings in tolerance class PN as per DIN 620-2.

Bearing clearance

We manufacture standardised spherical roller bearings with radial bearing clearance normal and C3 as per DIN 620-4, up to individually limited clearance classes.

Contact angle

–

Lubrication

The bearings are not greased and can be lubricated with grease or oil.

Connection with adjacent construction

Positive locking shaft-hub connection