Details

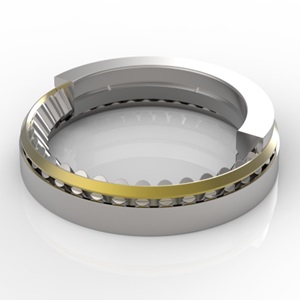

In axial spherical roller bearings, the forces acting at an angle to the bearing axis are transferred from one raceway to the other. Thus, the bearings are suited to absorbing additional radial forces where there is a simultaneous axial load. The angle can be adjusted and so they can be used to even out deflections and shaft misalignments in relation to the housing. Apart from that they are suited to absorbing the highest axial loads and permit relatively high rotation speeds. Axial spherical roller bearings are not self-restraining. Their individual parts – shaft washers, housing washers and roller assembly with the asymmetric spherical rollers – can be installed separately which makes fitting easier.

Special bearing

- –

Manufacture sizes

From an outer diameter of 100 mm.

Designs

- –

Bearing ring materials

Roller bearing steel (Standard)

Rolling elements materials

Roller bearing steel (Standard)

Heat treatments

–

Cage materials

Brass

Main dimensions

The main dimensions of the standardised axial spherical roller bearings comply with the specifications in ISO 104 and DIN 728.

Dimensional and running accuracy

We manufacture standardised axial spherical roller bearings in tolerance class normal as per DIN 620-3.

Bearing clearance

–

Contact angle

–

Lubrication

The bearings are not greased and should be lubricated with oil. Exceptionally, it is also possible to lubricate with grease.

Connection with adjacent construction

Positive locking shaft-hub connection