Details

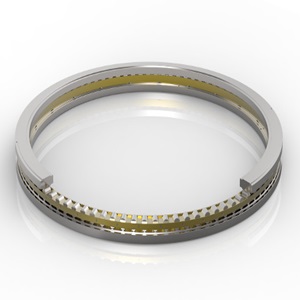

Single direction high precision axial cylindrical roller bearings are fitted particularly into tooling machines for turntable bearings. Their high axial load capacity at low axial construction height makes them a high-performance compact unit. Axial cylindrical roller bearings are not self-restraining. Their individual parts – shaft washers, housing washers and roller assembly – can be installed separately which makes fitting easier.

Special bearing

- Large, high-precision axial cylindrical roller bearings with special cage-constructions

- High precision needle axial cylindrical roller bearings

- Double direction axial cylindrical roller bearings

Manufacture sizes

From an outer diameter of 100 mm.

Designs

- Single-row axial cylindrical roller bearings (single direction)

- Double-row axial cylindrical roller bearings (single direction)

Bearing ring materials

Roller bearing steel (Standard)

Rolling elements materials

Roller bearing steel (Standard)

Heat treatments

–

Cage materials

Brass, steel pin type cage with perforated (FX®) rollers

Main dimensions

The main dimensions of the standardised single direction axial cylindrical roller bearings of the size series 811,812 (single-row) comply with the specifications in DIN 722 / ISO 104, the standardised single direction axial cylindrical roller bearings of the size series 894 (double-row) with the specification in DIN 616 / ISO 104.

Dimensional and running accuracy

We manufacture standardised axial cylindrical roller bearings in tolerance class normal to tolerance class P4 as per DIN 620.

Bearing clearance

–

Contact angle

–

Lubrication

The bearings are not greased and can be lubricated with grease or oil.

Connection with adjacent construction

Positive locking shaft-hub connection